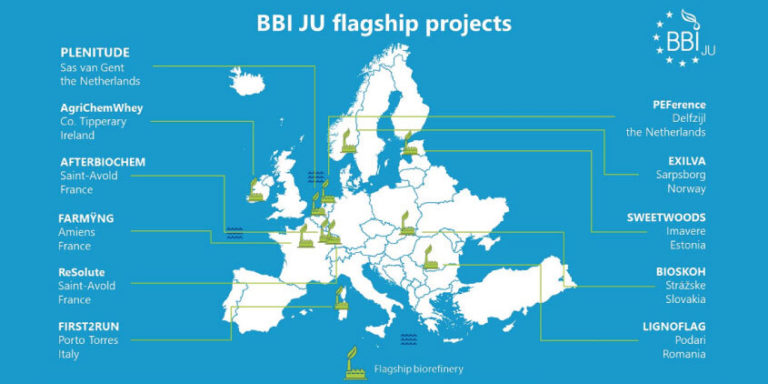

Avantium making progress towards investment in Delfzijl plant

Avantium, a leading technology company in renewable chemistry, has completed the application validation for its plant-based glycols plantMEG™ and plantMPG™ produced in the Ray Technology™ demonstration plant in Chemie Park Delfzijl. Key applications include polymerisation to PEF and PET polyesters and functional fluids used for de-icing and heat transfer. Consequently, proving the functional performance of the plant-based glycols is an important step in the scale-up of the Ray Technology™. Both plantMEG and plantMPG are expected to significantly reduce greenhouse gas emissions compared to their fossil-based equivalents.

Ray TechnologyTM

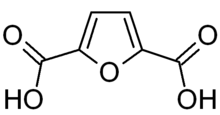

In 2020, Avantium successfully commissioned its Ray Technology™ demonstration plant. The plant utilises all process steps in converting industrial sugars to glycols, allowing for the production of plantMEG and plantMPG samples. Therefore, samples are representative of the final product from subsequent commercial-scale plants. Avantium has now produced 100% plant-based PEF by polymerising Avantium’s monomers FDCA (furandicarboxylic acid) and plantMEG. Ray plantMEG can also be used to produce bio-PET (30% plantMEG), reducing the environmental footprint versus the fossil-based production routes.

MEG and MPG applications

Currently, MEG is widely used as an important chemical building block for plastic bottles and packaging, polyester textiles for clothing and furniture, and antifreeze applications. Mono-propylene glycol (MPG) is a chemical used in airport operations for the de-icing of airplanes. In addition, it is also used in unsaturated polyester resins, for example in modern windmill blades, as well as heat transfer fluids. Ray plantMPG™ is a wholly plant-based version of MPG.

Commercial contracts for FDCA and PEF

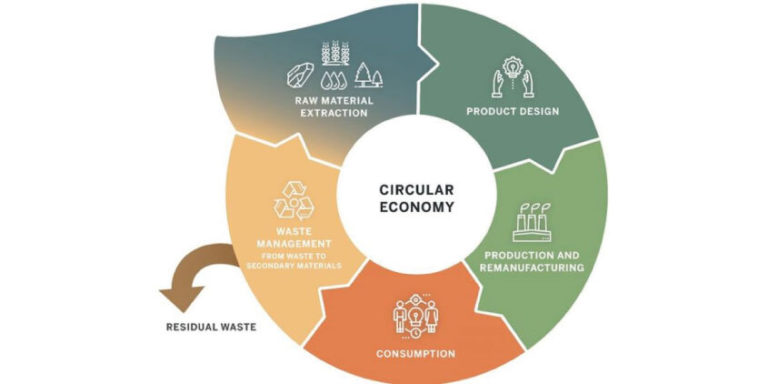

in seperate news Avantium has signed commercial contracts with Toyobo, Terphane, Refresco and Resilux for the supply of PEF bottles for its planned FDCA flagship factory. CEO Tom van Aken: “Avantium looks forward to welcome more partners with a shared ambition to make the transition to a next generation of materials for a circular and more sustainable future.

PEF polyester

PEF (polyethylene furanoate) is a polyester made from MEG and FDCA. PEF produced by Avantium’s YXY® Technology is a 100% plant-based and recyclable polymer”. The polymer can be used in an enormous range of applications, including packaging for soft drinks, water, alcoholic beverages and fruit juices. PEF’s barrier and thermal properties are superior to conventional PET. In combination with a significantly reduced carbon footprint, the added functionality gives PEF all the characteristics to potentially become a next-generation polyester.