Braskem invests 61 mio US$ in biobased ethylene

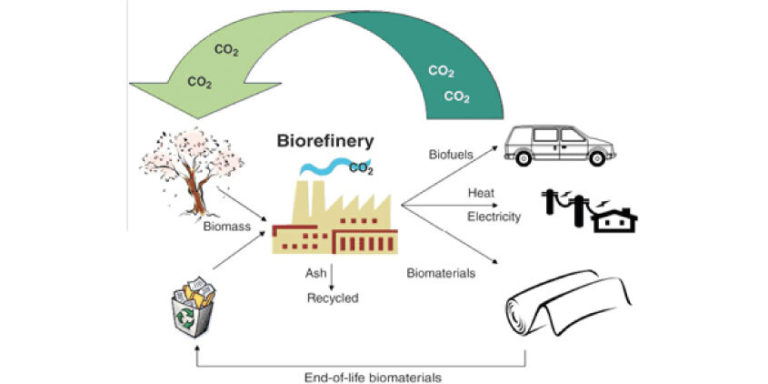

Braskem is expanding its production capacity of green ethylene, the main feedstock derived from sugarcane ethanol. Bioethanol is used in the production of renewable resins, such as polyethylene and ethylene vinyl acetate copolymer (EVA). These materials can claim to capture CO2. This raw material is produced at the company’s plant in Triunfo, Rio Grande do Sul. The plant’s capacity will be increased to 260 kton/year. Ten years ago Braskem started with 200 kt capacity for biobased polyethylene.This was complemented by EVA production in 2018.

Healthy market growth

The increase in biopolymer capacity and production reflects healthy growth in demand for sustainable products in recent years. The investment in research and development has been a strategic priority for Braskem. Activities are guided by increasingly sustainable practices, processes and production.

Research center in Brasil

Since 2007, the company has been researching technologies for producing green ethylene from sugarcane ethanol at its Technology & Innovation Center. The Center is located in the Triunfo Petrochemical Complex, in Rio Grande do Sul, Latin America’s largest and most advanced research complex for the industry. Braskem has invested US$290 million in the construction of an industrial unit for making the product in the region.

Same units as fossil-based production used

In 2010, Braskem announced the commissioning of the plant with production capacity of 200 kta. The transformation of green ethylene into bio-based polyethylene is carried out at the same polymerization units that produces the fossil-based resin. In 2018, Braskem expanded its offering of renewable solutions with the launch of bio-based EVA, an ethylene vinyl acetate copolymer with applications in the automotive and footwear industries, among others.