PHA’s (Poly Hydroxy Alkanoates)

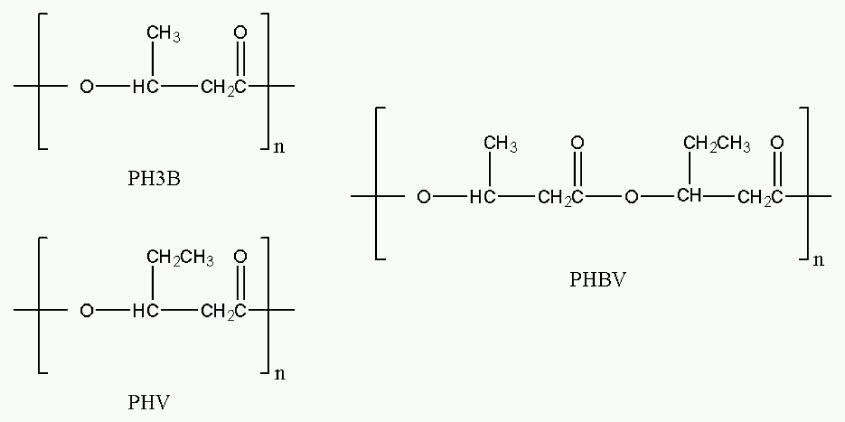

Polyhydroxyalkanoates (PHA’s) have been known by scientists for a very long time.x In fact, the simplest PHA, called P3HB, or sometimes just PHB, was discovered as early as 1926 by a French researcher, Maurice Lemoigne, in the course of his work with the bacterium Bacillus megaterium. At the time, little heed was paid to Lemoigne’s discovery, mainly because of its perceived irrelevance: at the time, fossil fuels were inexpensive and abundant. But all that started changing when, in the 1970s, the oil crisis started and bio chemicals and plastics started to become viewed as a viable alternative to petroleum-based materials. It was around that time that microbiologists brought PHA to the attention of the industry.

PHA is a family of materials

The PHA-platform is made up of a large variety of bioplastics raw materials made from many different renewable resources. Depending on the type of PHA, they can be used for applications in films and rigid packaging, biomedical applications, automotive, consumer electronics, appliances, toys, glues, adhesives, paints, coatings, fibers for woven and non-woven and PHA products inks. So PHAs cover a broad range of properties and applications.

So, what makes PHA’s so special? In the first place, PHA is not a single material, but a family of materials. PHA is nothing other than an energy storage material produced by different kinds of bacteria that can be harvested and processed into pellets. It’s the first polymer family to be produced by fermentation. Various PHA producing microorganisms have already been identified. Moreover, by changing the feed substrate of the microorganisms different types of PHA can be produced, which exhibit very different thermo-mechanical properties – from stiff and brittle to crystalline polymers to thermoplastic elastomers with low crystallinity and tensile strength with high elongation to break.

PHA’s can replace a range of plastics

Hence, PHAs have the potential to replace not just one, but a range of traditional plastics. For example, Newlight Technologies (Costa Mesa, CA), a major PHA producer, says its AirCarbon is able to meet the performance requirements of a wide range of applications, including applications currently using fossil fuel-based—HDPE, LDPE, LLDPE, PP, HIPS, ABS, acrylic, and TPU. It offers better performance than alternative bioplastics, such as PLA and starch, is fully biobased and biodegradable, some grades even in the marine environment.

Basically, this is why PHA has got so many people excited.

PHA market starts to gain traction

To date, however, PHA has failed to sparkle, performing more like a damp squib in the market. Extremely expensive to produce, its manufacturers have found it exceedingly difficult to find customers who willing to pay such a high price to be green. Moreover, performance problems were also reported. For a while, now, the market has been at a stage where there is high capacity but low consumption.

But things are changing and lately, PHA news has been coming in fast and thick. Newlight Technologies is using advanced biological carbon capture technology. And industrial biotechnology company TerraVerdae BioWorks Inc., in Canada, announced that it successfully completed the scale-up optimization of its process to produce biodegradable PHA bioplastics from waste-derived methanol at commercial scale. Danimer Scientific is the biggest producer of PHA, based on a patent portfolio developed by P&G. Kaneka Biopolymers produces a PHA variant called PHBH,

PHA scale crucial for lower cost

The difference is, these newer players in the PHA market are promising that their PHA is affordable, even competitive, in comparison to traditional polymers. They’ve invested in R&D to iron out performance problems and have developed less expensive production technologies. They’ve successfully manufactured PHA at scale—a prerequisite for an affordable product. Newlight Technologies, for example, developed a biocatalyst that generates a polymer conversion yield that is over nine times higher than before, enabling as the company has repeatedly said, its AirCarbon to out-compete oil-based plastics, such as polypropylene and polyethylene, on price. Netherlands based company Paques is developing technology for production of PHA from wastewater.

New polymers take time to take hold

Yet what also counts is the fact that it simply takes time for a new polymer to gain acceptance on the market. As Jan Ravenstijn, a Dutch biopolymers consultant with special expertise in PHA points out: “DSM’s Dyneema was patented in 1978, but only became profitable 20 years later. The same holds for Stanyl—a PA4,6, and Styron. Why should it be any different for PHA?”